Table of Contents

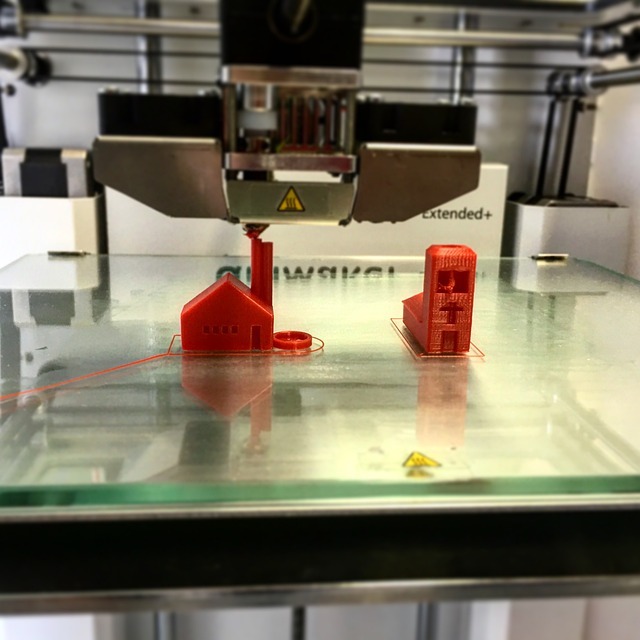

3D Printed Models has the ability to envision and convey design concepts plays a vital role. Traditionally, architects relied on handmade models crafted from materials like cork, balsa wood, and foam. While these models were effective, they demanded a great deal of labor, time, and money. However, the emergence of 3D printing technology has provided architects with a powerful tool that has gradually replaced traditional handmade models.

Benefits of 3D printing

The utilization of 3D Printed Models in design offers significant advantages in terms of cost and time savings. Unlike traditional models, 3D printers require a smaller initial investment and have lower production costs. This means that architects can create more models at a fraction of the cost and in less time. The printing process is highly efficient, allowing architects to dedicate more time to the overall design and elements that require emphasis.

Precision of 3D-Printed Models

Moreover, 3D Printed Models enables designers to produce objects with exceptional precision and detail. The printers can adjust nozzle sizes to enhance printing details, resulting in highly accurate representations of the design. Architects have the freedom to select the most suitable materials and machines for each model, ensuring that the printed models truly capture the desired structural and aesthetic qualities. Additionally, 3D printing allows for the creation of smooth surfaces and intricate details, which can be further enhanced through painting techniques.

3D-Printable Models

Another significant advantage of 3D printed models is the improved communication and collaboration among architects, clients, and other stakeholders. Architects can generate multiple versions of 3D printed models throughout the design process, facilitating easy comparison and evaluation of different design options. This iterative process empowers designer featured and clients to make informed decisions and provide timely feedback. Additionally, 3D printed models enable designers to engage in multiple meetings and discussions with colleagues and clients, collecting collaborative responses in real-time and making quick adjustments without excessive time or cost investment.

Challenges of 3D Printing

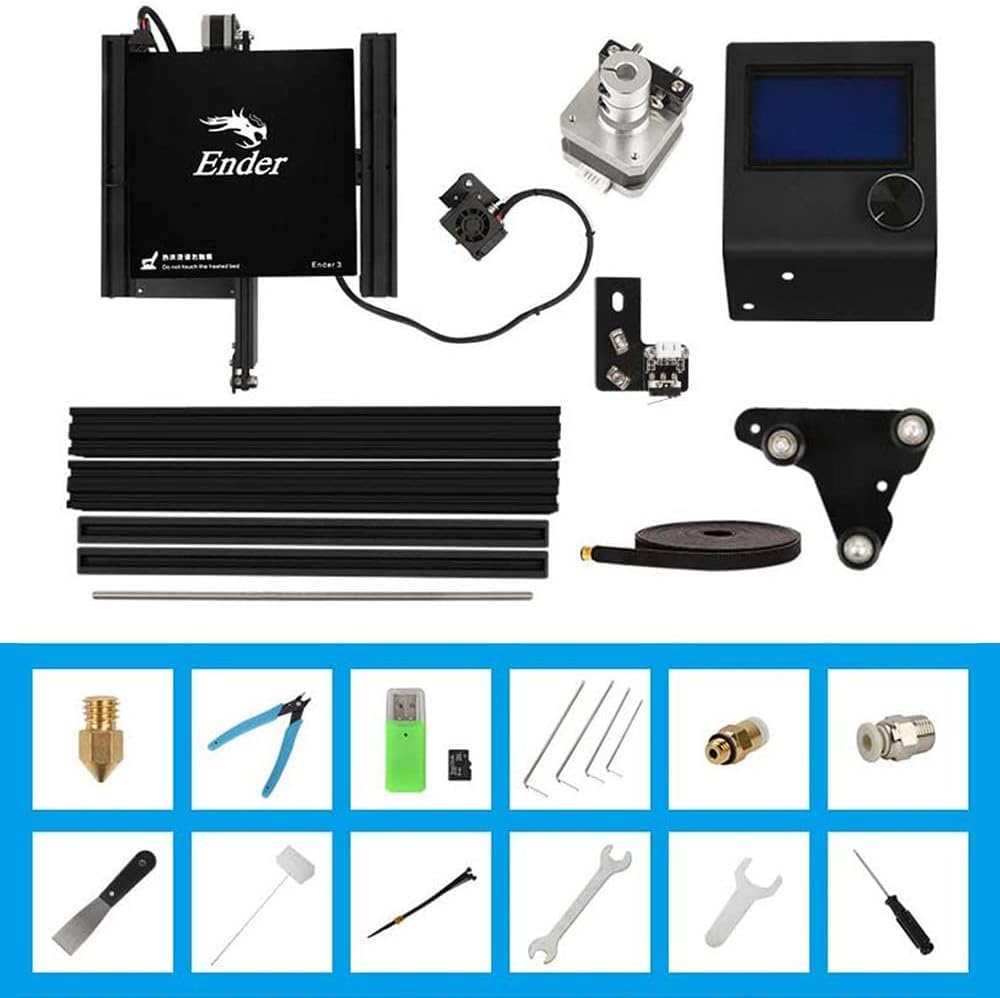

Nevertheless, there are still challenges to overcome in the implementation of 3D printed models in designs. One challenge lies in the selection of appropriate materials and ensuring optimal adhesion performance. Consistency in results is crucial, particularly for batch production. Additionally, the shrinkage rate of materials can impact large-format printing, potentially leading to warping or distortion in the model. Designers must carefully choose materials with low shrinkage rates and implement suitable heating techniques to maintain the integrity of the models.

Another challenge is the extended printing time required for larger models, which can range from 100 to 300 hours. Designers must ensure the reliability of 3D printers to operate continuously for extended periods without interruptions or failures.

Evolve of 3D Printing Technology

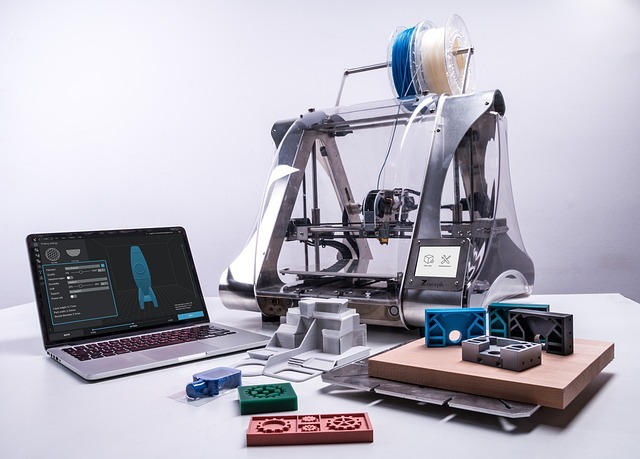

In conclusion, as the field of creative design continues to evolve, the integration of 3D printing technology has become an essential tool for ideas. The combination of digital design and 3D printing allows for more efficient, cost-effective, and detailed architectural models. Designers now have the ability to create models that accurately reflect their design vision, effectively communicate with clients, and make informed decisions throughout the design process.

Possibilities

With ongoing advancements in 3D printing technology, featured designer can anticipate even better results, more affordable printing services, and improved software tools. The fusion of traditional model making with 3D printed models technology has elevated model design to new heights, providing architects with the means to validate ideas and create stunning visual representations of their designs. Membership for 3d resources web application are readily available for downloading.

Additional Information:

Advantages

• 3D printing technology has also revolutionized other industries, including medicine and manufacturing.

• The use of 3D printers in design flow allows for the creation of intricate details and complex geometries that would be challenging to achieve with traditional model-making techniques.

• The ability to print models in smaller parts and assemble them offers greater flexibility and customization in the design process.

• 3D printed models has the potential to reduce construction waste by enabling architects to test and refine designs before construction begins.

• The adoption of 3D printed models in designs has resulted in increased efficiency, reduced costs, and improved design outcomes.

Hand-made models versus 3D printed models

Plastic model kits are known for their intricate and precise parts, capturing even the smallest details. Building these kits enhances fine motor skills and patience through the hands-on experience of cutting, gluing, and painting. They come in a wide variety of scales and subjects, such as aircraft, cars, ships, and figures. While there is some room for customization through painting and modification, it is within certain boundaries. The hobby of building plastic models has a strong community with forums, clubs, and events, creating a sense of nostalgia for enthusiasts. In terms of cost, plastic model kits are generally more affordable than 3D printing.

Unlimited Creativity

On the other hand, 3D-printed models offer unlimited possibilities for customization and design. With the ability to modify or create designs from scratch, there is unparalleled creative freedom. 3D printable models can reproduce intricate and complex shapes that may be challenging or impossible with traditional injection molding.

The versatility of 3D printing materials allows for a wide variety of finishes and properties, ranging from plastics and resins to metals. Rapid prototyping is made easier with 3D printing, enabling quick iterations for testing and modifying designs. Working with 3D printed models involves a digital workflow, appealing to those with a background or interest in digital design and computer-aided design (CAD). In terms of environmental considerations, 3D printing generates less waste compared to traditional plastic model kits.

Ultimately, the choice between plastic model kits and 3D printed models depends on personal preferences, skill sets, and specific goals. Some may enjoy the traditional craftsmanship of plastic models, while others may prefer the digital design and customization possibilities offered by 3D printing.